Diamond Wires

The future of natural stone from the quarry or from the block is the diamond wire!

In the quarry work performance diamond wires, the granite with up to 25sqm / h away from the mountain. Values that were only imaginable in marble 20 years ago.

Now working in the production plant Multi wires sawing with 80 and more ropes cutting 40sqm / h and also far beyond! The case of a kerf of 6.3mm. Superlatives, highlighting the stone in a new dimension of faster availability.

DIABÜ® manufactures high quality diamond wires for Multi saws, block wire saws, contour saws and quarry saws. Our entire product range is for you as a download ready in Chapter Diamond Wires.

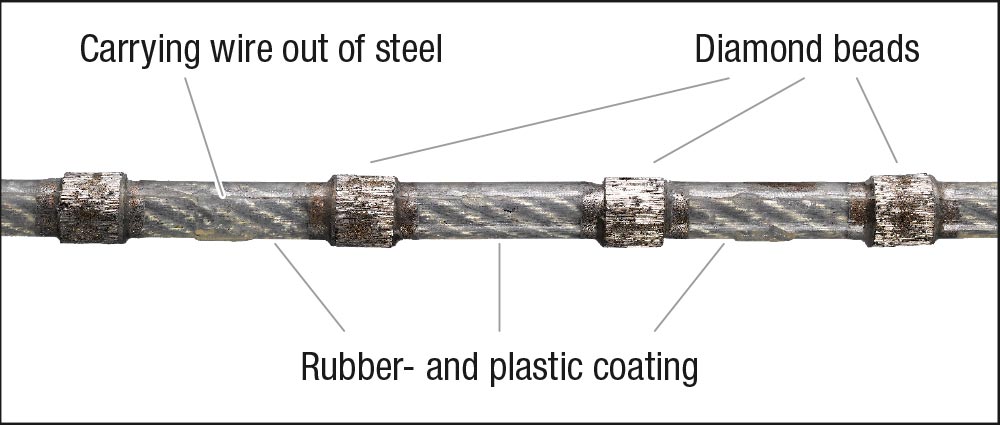

The diamond wire consists of:

- a carrying wire out of steel

- diamond beads

- a rubber or plastic coating

The steel wire works as a carrier for the beads and the rubber or plastic coating. For this we only use special high load open twisted wires, whose engineered structure ensures a perfect wire rotation with appropriate pre-twisting.

The beads equipped with a diamond mantle segment carry out the actual cutting work. The base of these beads is a cobalt alloy, which has already proved its performance on our segments for diamond circular saws. This base has been modified in order to achieve optimum free cutting and long life characteristics for the wire saw. Embedded into this metal alloy is a diamond quality, which was chosen specifically for the use on diamond wire due to its extreme fractural strength and high quality crystal structure.

The rubber or plastic coating protects the carrier wire from corrosion and from the grinding effect of the material to be sawn. It is also responsible for the fixed sit of the diamond beads on the wire.

The use of new developed plastics or elastomer and their subsequent treatment techniques guarantee the high resistance to aging, the necessary wear and abrasive resistance and the indispensible wire flexibility even under extreme conditions of application.